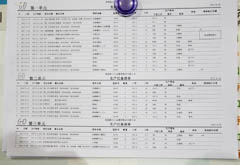

Design management

For one part design, the design lead time at least can be shortened by half.

Your Position:Home > About Us > Management

For one part design, the design lead time at least can be shortened by half.

High-end build ERP system make good arrangement and deploy of production plans and sources.

01Reception of parts

02reception of procedures

03parts putting

04procedures matching.

01ERP planning

02plans output

03plans execution

04Production preparation

01execute plans

02prepare in advance

03self-check off machines

04scan and Logistics

Advanced factory layout, to optimize and shorten the molds delivery time.

Combination of hardware and software, intelligent manufacturing techniques, ahead of the world.

WeChat

WeChat