Production Equipment

- CNC Equipment

- Precision graining device

- WEDM deivice

- EDM deivice

- Detection device

- Try equipment

- Others

-

MCD1816

With 15000r/min high speed main axis, which covering thermo stabilization device, so that to keep stable machining temp., improve machine accuracy. Including B axis circular dividing table, it can reach 3+1 axis machining and clamping one time, multi-aspect machine.

-

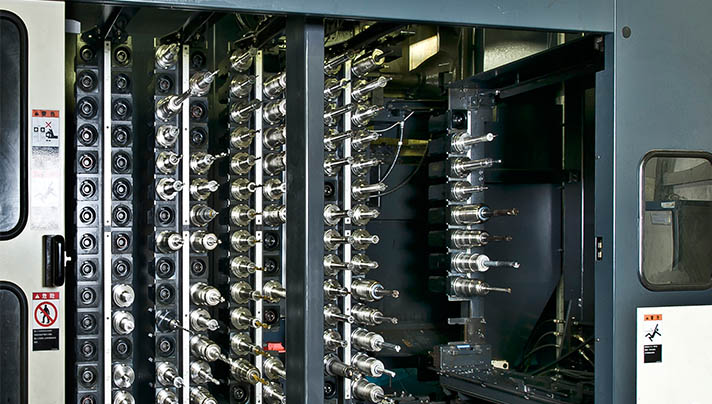

A100E

Only 2 sets in mainland China, two working tables can be switchover automatically, and with 302 pcs ATC tooling warehouse, which can achieve full-automatic machining.

-

Graphite

Makino precision graphite CNC stroke (mm) to achieve 650*500* 450, the maximum load of work platform (KG) 650.

-

A66E

A66E,only 1 set in mainland China, 8 working tables can be switchover automatically, which realize 24h unattended operation.

-

5 axis

MP-2618(5C) (5 axis ): Realize 3+2 axis machining, with A axis ┬▒30┬░maximum swing angle, C axis can realize ┬▒360┬░rotation, Y axis maximum stroke is 3m, mainly for huge and deep component machining, such as light tool.

-

Precision graining device

Imported from Japan, co-axiality reach 0.002, and surface degree reach RA0.05.

-

WEDM deivice

This machine can cross copper wire automatically and AR function, which is unnecessary to correction dept of parallelism, and it can realize ┬▒0.002mm during machining.

-

EDM

TURBO 2500CNC Double-head EDM, specializes in processing large-scale automotive toolings, which improves the efficiency over 50%.

-

EDM

This machine owns its ATC electrode storage, and over 1000 kinds machining condition to meet each kind of complicated component, which could reach ┬▒0.005mm precision and Ra0.2╬╝m during machining.

-

FQC

Video measuring system: VMS-6060H ’╝īX/Y/Z digital readout’╝Ü0.5╬╝m’╝ø

Coordinate measuring machine: Quick View 300S CNC’╝īdigital readout’╝Ü0.0001mm’╝ø

Roundness measuring instruments: RONDCOM41C’╝īdigital readout’╝Ü0.0001mm’╝ø

Surface texture and contour measuring instruments: SURFCOM1800D-12’╝īprecision’╝Ü0.0002mm’╝ø

Image size measuring instrument: IM-6010 , precision’╝Ü0.010mm’╝ø

-

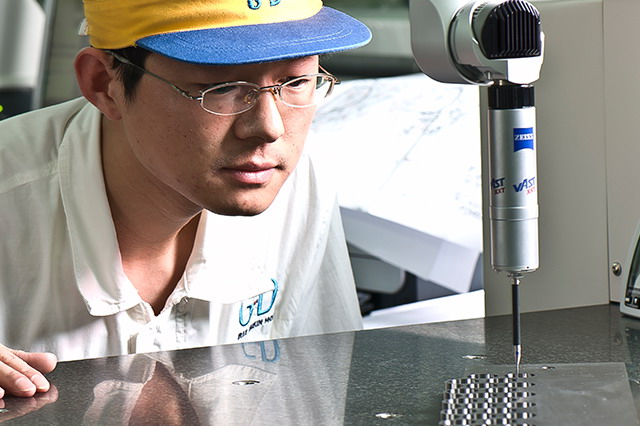

IPQC

IPQC German Zeiss CMM with three-dimensional system, CONTURA G2 776 RDSŃĆüCONTURA G2 10216 RDS, which can measure hook face and 1.8╬╝m precision.

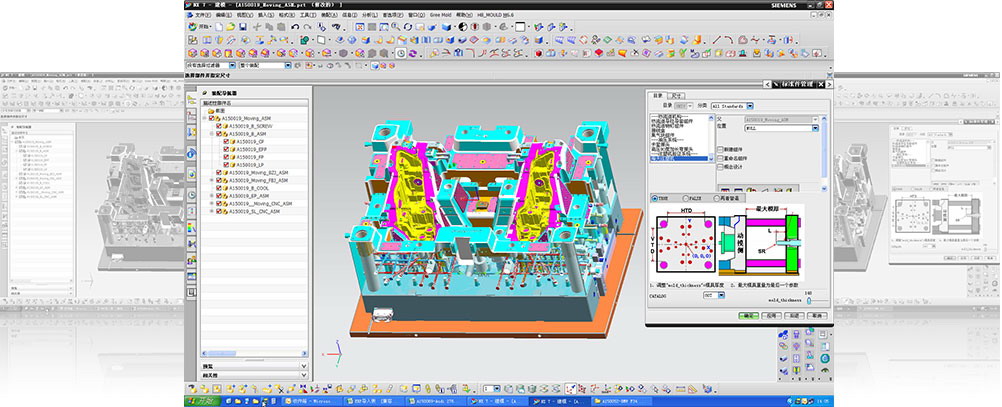

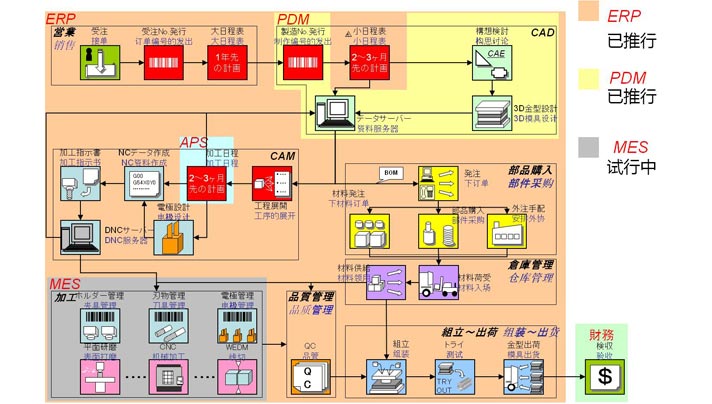

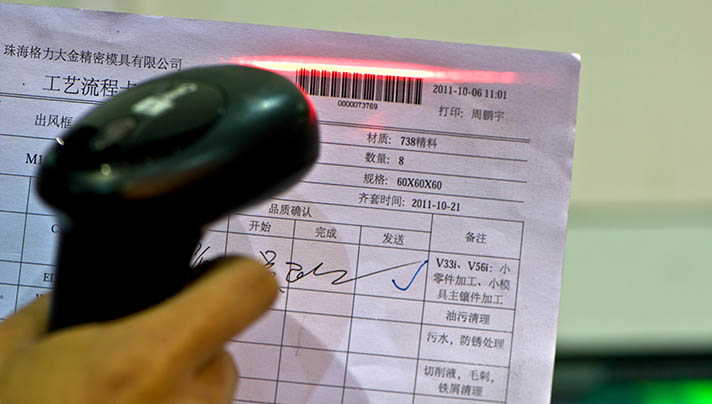

Information management

Information management

Safety management

Safety management

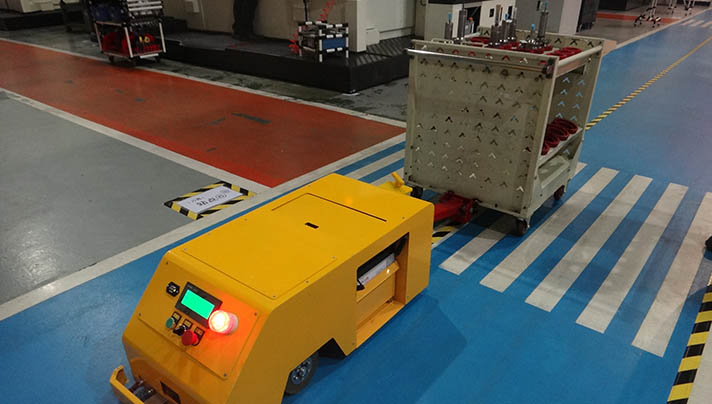

Automated management

Automated management

5S management at factory

5S management at factory

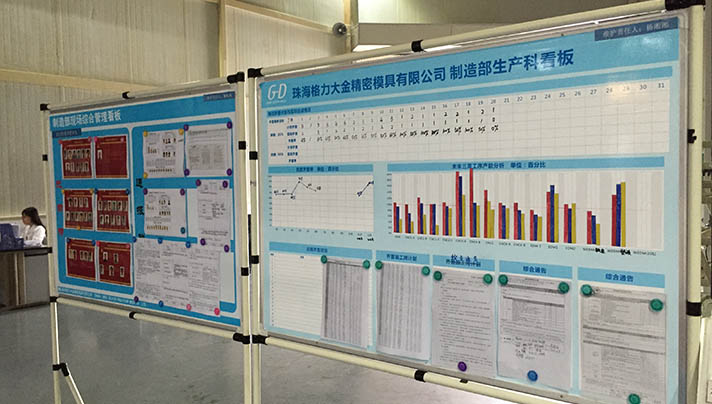

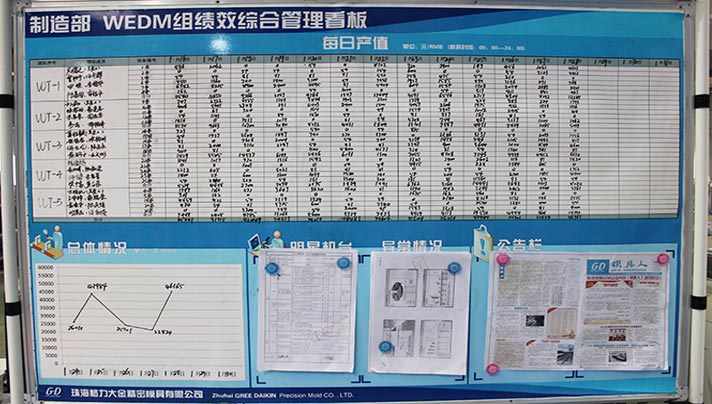

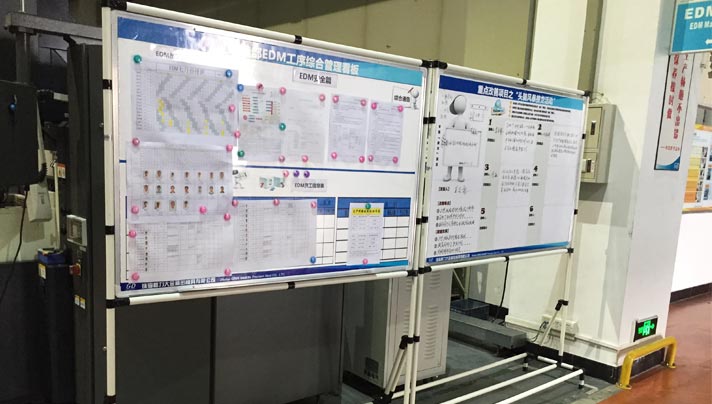

Japanese style board management

Japanese style board management

WeChat

WeChat